Ch 7. Subspecialty: Haz-Mat

The hazardous materials (haz-mat) category includes materials that are radioactive, flammable, explosive, corrosive, oxidizing, asphyxiating, bio-hazardous, toxic, pathogenic, or allergenic.

The aim of emergency personnel should be to make a chemi- cal-specific identification while exercising caution to prevent ex- posure to any chemicals. Identifying the hazardous material and obtaining information on its physical characteristics and toxicity are vital steps to the responder’s safety and effective manage- ment of the haz-mat incident.

If release is suspected:

- Remain calm.

- Put on personal protective equipment (PPE).

- Reassure victims that assistance is on the way.

- Wait for properly equipped help at a safe location (upwind, upstream).

Incident Objectives

- Secure perimeter and designate zones of operation.

- Identify and control agent.

- Rescue, decontaminate, triage/treat/transport affected individuals.

- Move uninvolved crowd/persons to safe zones.

- Stabilize the incident.

- Avoid secondary contamination.

- Secure evidence and crime scene.

- Protect against secondary attack.

Six primary clues to hazardous materials

Occupancy and Location – Obvious locations in the com- munity that use and/or store hazardous materials include labora- tories, factories, farms, paint supply outlets, construction sites, etc.

Container Shape – Haz-mat transport container specifica- tions are regulated by the Department of Transport (DOT).

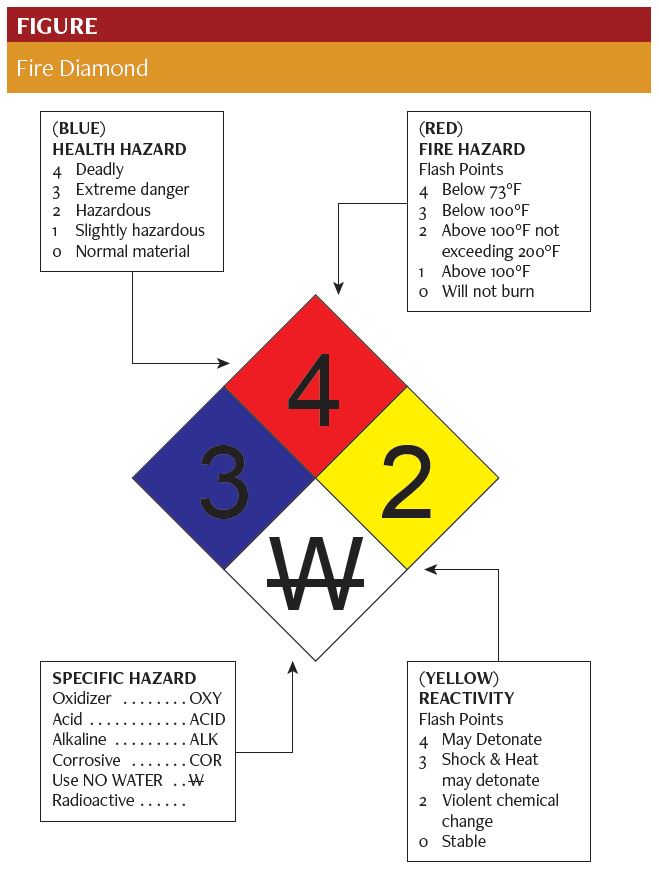

Markings/Colors - Marking scheme designed by National Fire Protection Association (NFPA 704M system) identifies hazard characteristics of materials at terminals and industrial sites (but does not provide product-specific information).

Placards/Labels - Hazard class wording or four-digit identi- fication numbers, placards used when hazardous materials are stored in bulk (>1001 lbs), and labels identify smaller packages.

Shipping Papers - These are required to have a 24-hour emergency information phone number. Provides shipping name, hazard class, ID number, quantity, and may indicate if the materi- al is waste or poison.

Senses – Odor, vapor clouds, dead animals/fish, fire, skin/eye irritation can signal the presence of hazardous materials. People can be biological detectors (coughing, choking, vomiting). Some chemicals can impair an individual’s sense of smell (eg, hydrogen sulfide) and others have no odor/color/taste (eg, CO).

NFPA 704 Marking scheme (Fire Diamond)

This is the standard system for the identification of the haz- ards of materials for emergency response. (Figure)

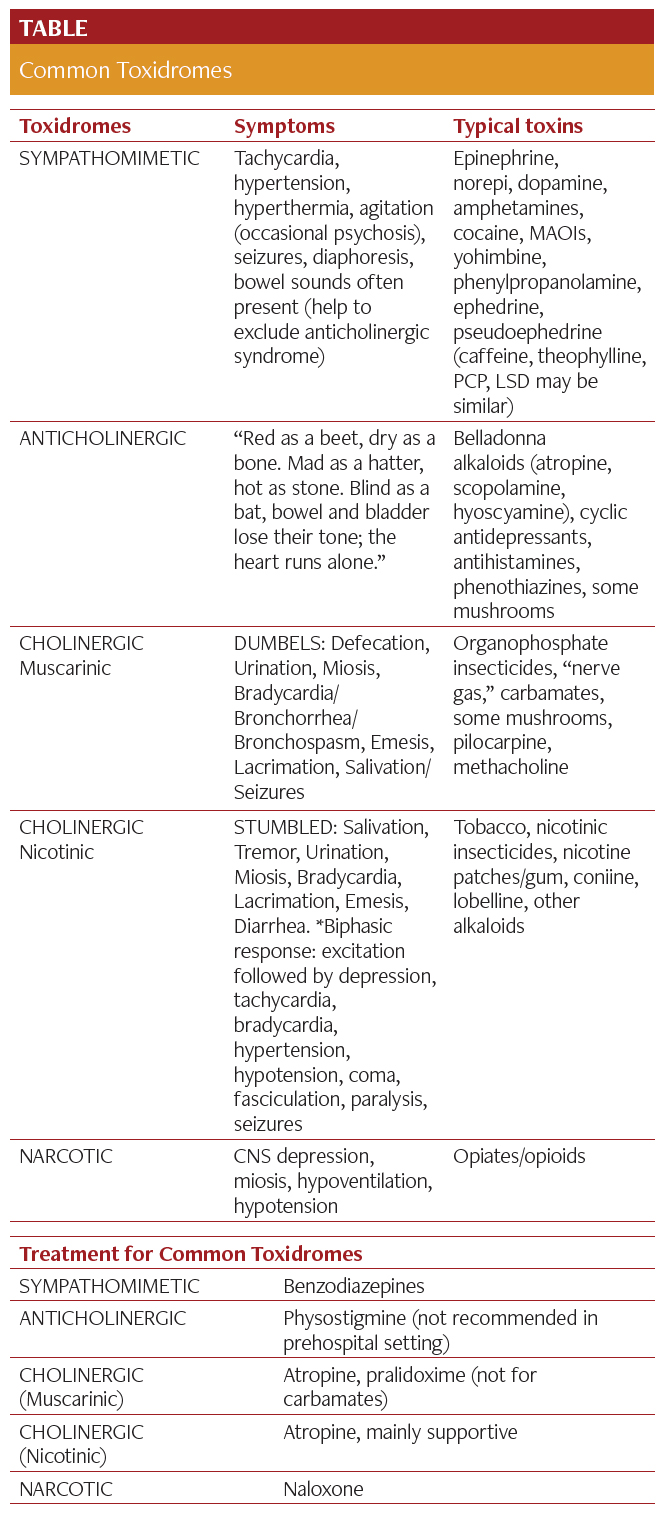

Recognition of Common Toxidromes

- constellation of clinical clues to identify the poison. Begin with vital signs and mental status, then add other autonomic indicators. (Table)

Personal Protection Equipment (PPE)

Personal protection equipment (PPE) is used to isolate or shield individuals from chemical, physical, and biological hazards. The use of PPE itself creates significant worker hazards, such as heat stress, physical and psychological stress, and impaired vision, mobility, and communication. In general, the greater the level of PPE protection, the greater the associated risks. Person- nel should not use PPE without adequate training (specific train- ing is mandatory).

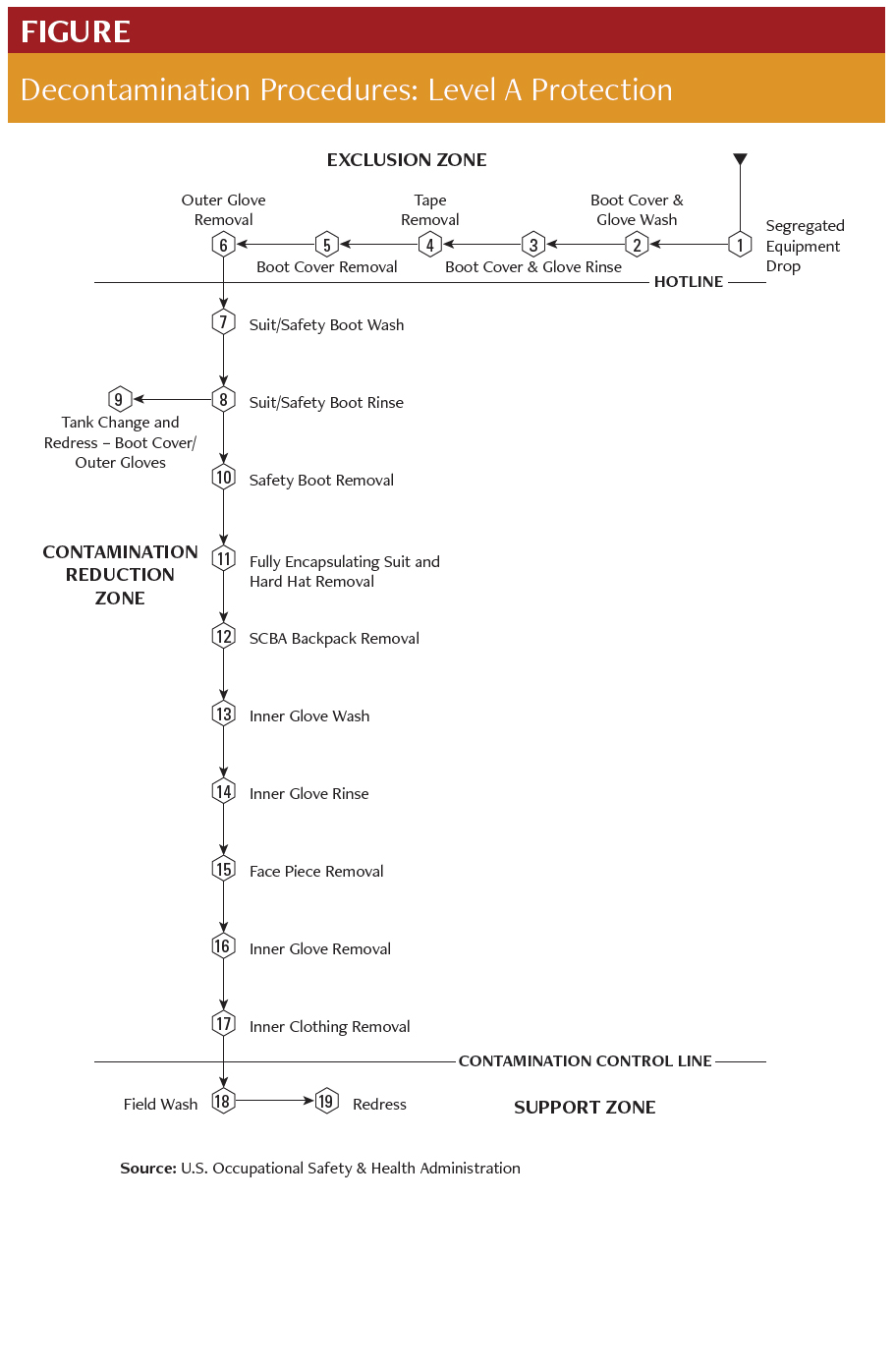

Level A protection: Fully encapsulated vapor-tight, chem- ical-resistant suit, chemical-resistant boots with steel toe and shank, chemical-resistant inner/outer gloves, coveralls, hard hat, self-contained breathing apparatus (SCBA).

Level B protection: Differs from Level A only in that it pro- vides splash protection through use of chemical-resistant cloth- ing.

Level C protection: Same degree of skin protection as Level B, but a lower level of respiratory protection.

Level D protection: Primarily a work uniform. No respiratory protection, minimal skin protection.

Respiratory Protection

There are 2 basic types of respirators: air-purifying and at- mosphere-supplying. Atmosphere-supplying respirators include self-contained breathing apparatus (SCBA) and supplied-air respi- rators (SAR).

Air-Purifying Respirators (APRs)

Purifies ambient air by passing it through a filtering element before inhalation. The advantage is mobility; however, it requires sufficient oxygen (19.5%) since it depends on ambient air to function. APRs should not be used when substances with poor warning properties are involved or if the agent is unknown, or when the environmental levels of a substance exceed the capac- ity of the canisters. Powered air-purifying respirators (PAPRs) have the advantage of creating an improved seal, thus reducing the risk of inhalation injury. PAPRs come in masks or pullover hoods; men with beards can wear the hooded system but not the full facemask.

Atmosphere-Supplying Respirators

A self-contained breathing apparatus (SCBA) contains its own air supply, with a face piece connected by a hose to a com- pressed air source.

- A Supplied Air Respirator (SAR) depends on an air supply provided through a line linked to a distant air source. It allows personnel to work longer than SCBA, and it’s less bulky than SCBA. The air source has to be within 300 ft.

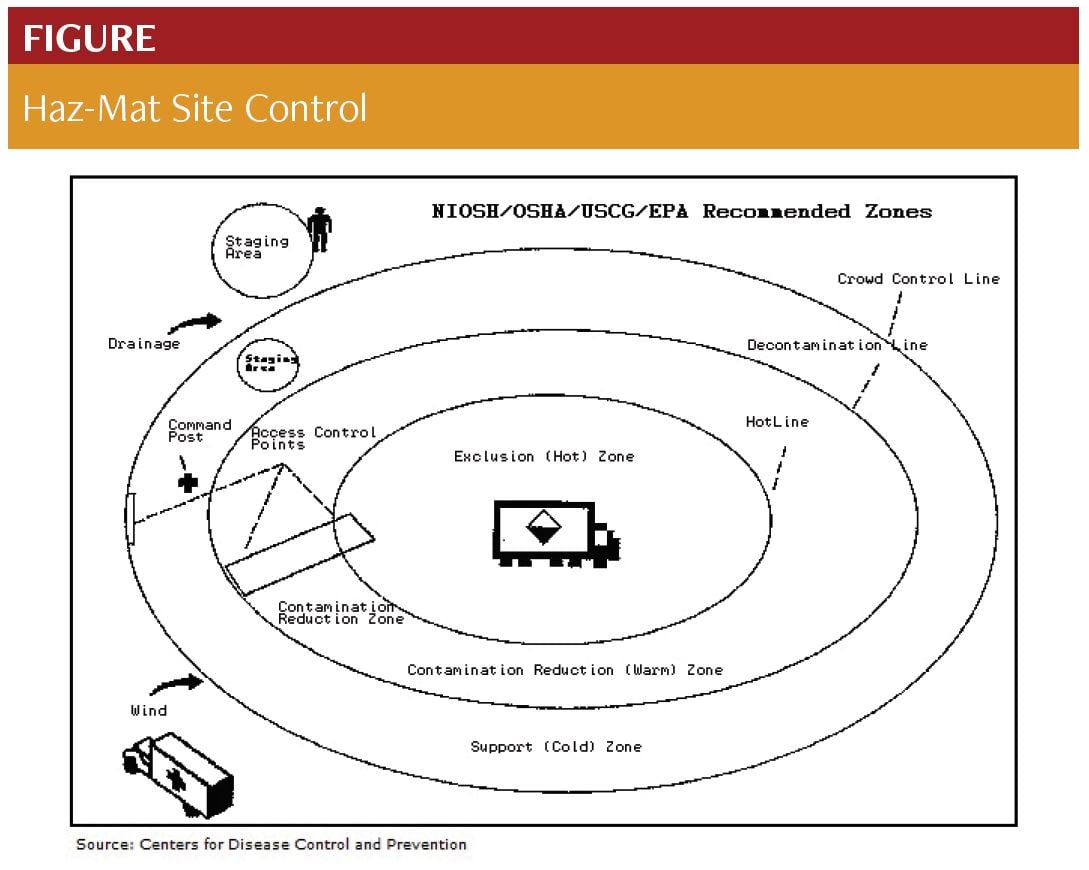

Site Control

Hazardous materials incidents often attract large numbers of people and equipment. This complicates the task of minimizing risks to humans, property and environment. (Figure)

Exclusion (Hot) Zone: This “ground zero” perimeter should encompass all known or suspected hazardous materials contami- nation.

Contamination Reduction (Warm) Zone: A secondary zone of protection is determined by the length of the decontamination corridor, which contains all of the needed decontamination stations.

Support (Cold) Zone: The outermost zone is free of all haz- ardous materials contamination, including discarded protective clothing and respiratory equipment. *Command post and staging areas for necessary support equipment should be located in the support (cold) area, upwind and uphill of the exclusion (red) zone.

Personnel decontamination method

Be aware of telephone and computer-based information sources concerning hazardous materials. The regional Poison Control Center, Soldier and Biological Chemical Command (SB- CCOM), and Centers for Disease Control and Prevention (CDC) can be contacted 24 hours a day to provide vital information on the medical management of hazardous material exposures. (Figure)

References

1. NIOSH Pocket Guide to Chemical Hazards. Centers for Disease Control and

Prevention. http://www.cdc.gov/niosh/npg/.

2. Alibek K, Dashiell T, Dwyer A, et al. Jane’s Chem-Bio Handbook. 3rd ed. Surrey, UK: Jane’s Information Group; 2005.

3. USAMRIID’s Medical Management of Biological Casualties Handbook. 4th ed. Fort Detrick, MD: U.S. Army Medical Research Institute of Infectious Diseases; 2001.

4. Medical Management of Chemical Casualties Handbook. 4th ed. Aberdeen Proving Ground, MD: USAMRICD Chemical Casualty Care Division; 2007.